Negative values are below top.

Side Loaders

This method of lifting containers incorporates transverse mounted hydraulic arms integral with a lorry chassis. It uses a pair of two legged slings each being attached to the hook of the lifting arms, whilst the bottom ends are attached to suitable lifting lugs, these should remain insitu if ever the slings become slack. This attribute is what makes the Preston Shoe ideally suitable for use with these machines.

Sole Distributers UK 01384 636421 Intl. 441384 636421

Sling geometry when End Lifting

End Lifting sling angle range for Series 1 Containers.

End Lifting sling angle range for Series 1 Containers.

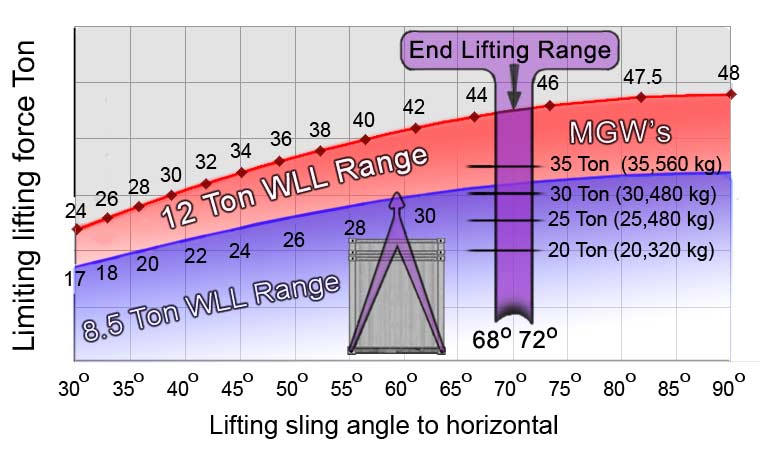

The sling geometry for single point end lifting is effective over a sling angle range between 68° and 72° typically 70°.

The sling arrangement determines the head room and normally they do not make contact with the end faces of container but lifting point may be below the roof of high cube units and with some machines, may make contact with the top end face of container.

H is container height. (Range: 8ft to 9ft 6in)

Negative values are below top.

Limiting Gross Weights when END lifting ISO containers

The limiting Gross Weight (GW) is determined from sling angle and Working Load Limits (WLL) of 8.5 Ton or 12 Ton for these lugs. The GW must not be exceeded and these are shown here in general limiting lifting force diagrams for Side Lifting over the sling angle range 68° to 72°. Uniformly loaded containers give the maximum permissible GWs. For eccentric loading the results give LOWER limiting GW values owing to additional sling forces at the" heavy end". The GW for the two loading cases of uniform and eccentric payloads are given below and must either equal or preferably exceed the MGW of unit being lifted.

Gross Weights for uniform loading, lugs loaded to WLL

Level loading maintained

Sling angle range

Sling angle range

Gross Weights

Gross Weights

α

Gross Weights

Gross Weights

Gross Weights for offset loading, lugs loaded to WLL

Eccentric Loading, Level lifting

Sling angle range

Sling angle range

Gross Weights

Gross Weights

α

Gross Weights

Gross Weights